Sometimes it’s helpful to see projects similar to the ones you’re planning. Below are some tank insulation case studies from past projects. We have many more, as well as more categories in the works.

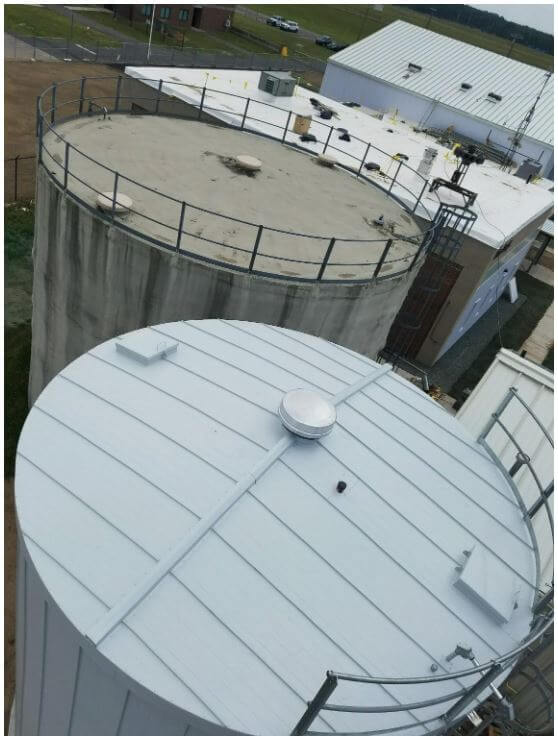

We work on your behalf, with the tank manufacturer, to coordinate important elements (such as flashing angles and appropriate roof design) so your project will be water-tight and protected properly.

Although most tanks have moderate temperature ranges, there are occasions in which we have to create composite or hybrid insulation systems that facilitate cryogenic or extremely hot tanks.

During installation of the tank panels, we require photos at important steps to ensure a quality install.

When our crews do the installation, they may NOT leave the site until they receive a favorable sign-off on our approval form.

Communication with everyone involved and managing expectations from the very beginning are key to a successful tank insulating project. From a robust and proven design to custom fabrication and experienced careful installation, our goal is always to exceed expectations.

We ask a lot of questions on the front end, and keep you updated with schedule milestones. We deliver when we say we will, and finish the job on-time.

To us, an insulated industrial tank is a work of art. Of course, not everyone appreciates such things, but we can’t help but take pride in a finished tank that looks sharp.

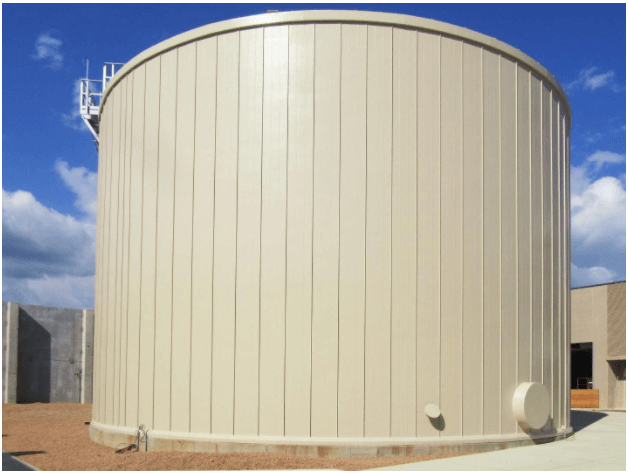

RIDGLOK® vertical standing seam insulation panel system on a bolted fire protection tank. The insulated roof and side shell are protected at the joint with customized flashing. Protuberances (penetrations through the panels) are easily adapted into the system.

Sometimes a tank is in a prominent position that makes it suitable for displaying branded signage. The installation of the industrial tank insulation was adapted to the needs of the lighted signage supports and electrical cabling. Since the final insulated tanks themselves are attractive, they make an excellent billboard.

Some customers prefer to add custom branded decals to their insulated municipality tanks. Lighting can be added from the ground to make the decals visible at night.

RIDGLOK® has a variety of roof adaptations to suit any industrial tank that requires insulation.

When tank specifications call for the tank roof and shell to be insulated, consider going with a system that can be adapted easily in a water-tight and durable fashion. Every tank is similar, but every tank is uniquely different. Creating insulation solutions for industrial tank projects with many variables is important. Creativity and a long experience with creating long-life low-maintenance solutions should be expected.

Bolted steel tanks, welded steel tanks, and concrete tanks all have different demands. Safety rails, man ways, vents, pipes, and ladders require a tank insulation system that adapts easily to keep quality high and labor costs low.

Unique tank requirements are the rule, not the exception. MCI-RIDGLOK coordinates with your tank manufacturer in advance to make sure there are no surprises for you during the final installation. Clear communication between all stake-holders makes for a tank insulation project that satisfies the client without any surprises.

Industrial tanks are located in a multitude of locations with a wide variety of connections. Adaptability and planning are key.

Dry storage (like grain silos, flour tanks, etc.) have their own issues. Where liquids in industrial tanks are insulated to control process temperatures or prevent freezing, dry solids have to deal with the complexities of condensation on the inside. Silos with dry solids are subject to molds because warm interior powder or grain is subject to an updraft as outer ‘uninsulated’ tank walls cool. Condensation from the inner tank wall falls, moves toward the center, then flows up to the top where a crown of ruined product can form.

In addition, with may dry solids, condensation creates clumping which makes it difficult to move the product. Air knockers and manual labor may be required to thoroughly remove old remnants from the tank walls.