Project Overview

This RIDGLOK® Vertical Standing Seam Panel Insulation System was manufactured at our facility in Reed, KY, for installation on a biodiesel storage tank used at an energy fuel storage depot.

The tank dimensions were 30’ in diameter x 39.56’ in height.

The tank required insulation to maintain the Bio-Diesel at 60° F during the cold snaps of winter in the South East.

Upon completion of the project, the customer stated that they would recommend both MC&I’s crew and RIDGLOK® to others. He also said that he was completely satisfied with the work completed.

Biodiesel Storage Challenges

The RIDGLOK® panel insulation provides freeze protection for the biodiesel fuel stored inside the tank. Biodiesel needs insulation in parts of the United States that drop below freezing because biodiesel tends to freeze, or gel, at higher temperatures than conventional diesel. The freezing temperature depends on the type of oil or fat that the biodiesel is made from.

A diesel fuel’s cold-weather characteristics are measured by the cloud point (CP), the cold filter plugging point (CFPP), and the pour point (PP). The cloud point is the temperature of the fuel at which small, solid crystals can be observed as the fuel cools. The cold filter plugging point is the temperature at which a fuel filter plugs due to fuel components that have crystallized or gelled. The pour point refers to the lowest temperature at which there is a movement of the fuel when the container is tipped.

Compared to petro-diesel, biodiesel tends to have a much narrower range of temperatures between the cloud point and the pour point. Those who are used to dealing with petro-diesel may be surprised at this narrow range. While there may be a 20-degree difference between the cloud point and the pour point of petroleum diesel, biodiesel may have a difference of only a few degrees.

Why Choose RIDGLOK®?

MC&I is the proud manufacturer of the RIDGLOK® Vertical Standing Seam Panel Insulation System for ground storage tanks. RIDGLOK® insulation systems are engineered to be energy efficient, durable, and cost-effective. RIDGLOK® can be used for both heated and cold storage applications without the need to take the tank out of service. This tank insulation system can be applied to all types of tanks, including flat bolted, chimed bolted, glass-lined, fiberglass, welded, stainless steel, and concrete. ADVANTAGES The RIDGLOK® vertical standing seam panel insulation system is a smart and efficient thermal barrier, helping save money on utility costs of heating and cooling the tank. Insulate your tank with RIDGLOK®!

The RIDGLOK® Vertical Standing Seam Panel Insulation system is used for freeze protection in biodiesel tanks. The panels can be applied to all types of tanks, including flat bolted, chimed bolted, glass-lined, fiberglass, welded, stainless steel, and concrete. The tank does not need to be taken out of service to install the system. Insulating fire protection tanks with RIDGLOK® Vertical Standing Seam Insulation provides energy savings by reducing the amount of electricity needed to heat the tank.

BEFORE: Biodiesel storage tank in Macon, GA

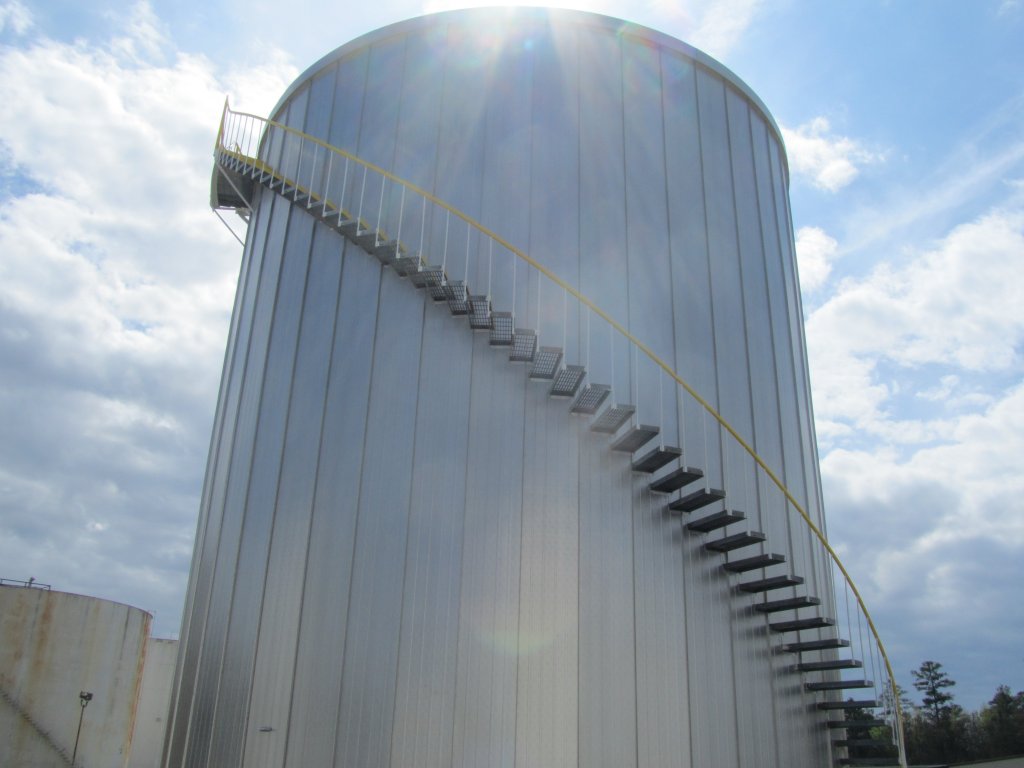

AFTER: Biodiesel storage tank insulated with RIDGLOK®

RIDGLOK® storage tank roof insulation