What Is Polyisocyanurate Insulation?

One type of insulation you can choose for your RIDGLOK® tank insulation system is polyisocyanurate insulation. This type of insulation is ideal for storage tanks in all industries because it does not absorb moisture (<1% Vol.) and can be used for both cold and hot operating temperatures (-40°F to 250°F). It also has a high R-Value of R-6 per inch. If you are not yet familiar with PIR or polyiso insulation, as it’s often called, here are some facts about this material:

How Is It Made?

Polyisocyanurate insulation is created from rigid, closed-cell foam. It has a core of foam in the center that has been placed between facers that provide a vapor barrier. Generally, these facers are made from fiberglass or reinforced aluminum foil.

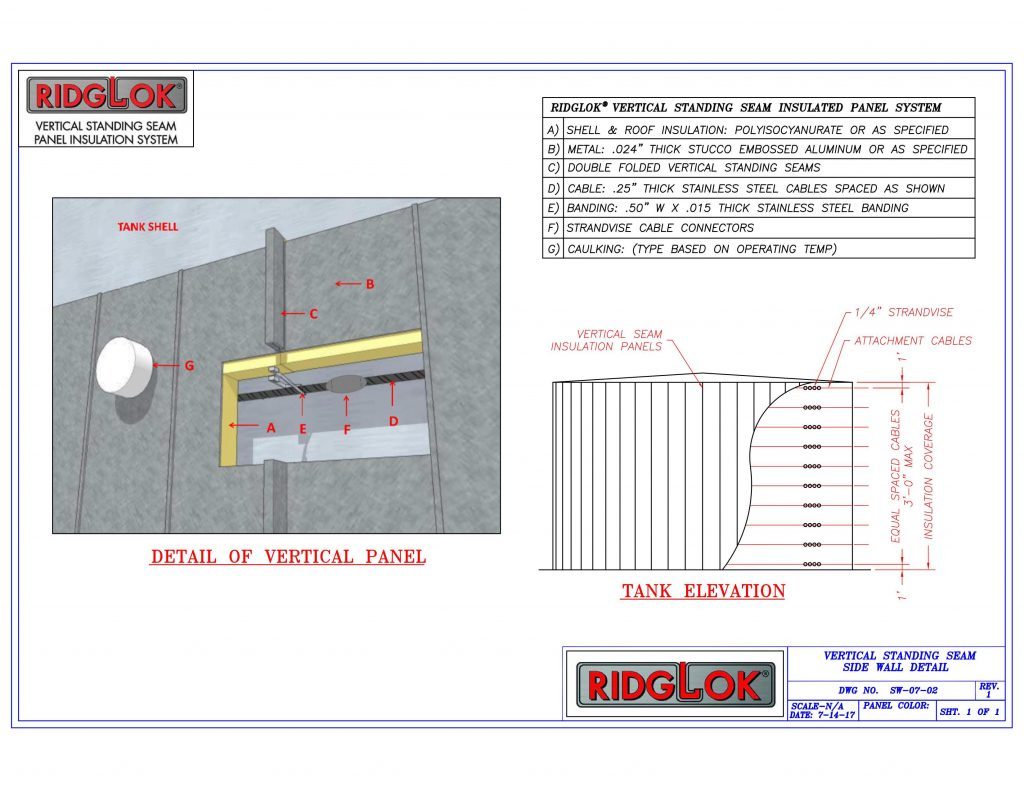

Polyiso is found in many different commercial and residential buildings, often used in the walls and roof. However, it’s also an ideal type of insulation to use for storage tank insulation systems, namely the Vertical Standing Seam Panel Insulation System (VSSI).

What Are The Benefits?

The biggest benefit to polyisocyanurate insulation is its R-Value per inch. It has the highest R-Value per inch out of any rigid foam board insulation, which means it’s very efficient and will greatly decrease the amount of heat or cold transfer between the tank contents and the atmospheric environment (<0.3 perms ASTM E96). Polyiso is unique in that the R-Value increases with the thickness of the foam, so three inches of polyiso has a higher R-Value per inch than two inches, according to www.polyiso.org. Tanks with RIDGLOK® VSSI systems (See image below) that use polyisocyanurate insulation will use less energy and keep the internal temperature of the tank very consistent in conjunction with heaters or chillers.

The compressive strength of polyisocyanurate insulation is structurally rigid at 20 psi (ASTM D1621). It will adhere to metal jacketing well and handle light foot traffic. The rigidity also helps maintain the structure of the VSSI Panel when installed in the field on storage tanks.

You can use polyiso insulation in environments that range from -40 degrees F to 250 degrees F. While it isn’t the most versatile insulation in regards to temperature range, it is still a good option for all tanks that must be kept at a consistent temperature under 250°F. The flame spread performance tested at 75 or less, however is available in a less than 25 option (ASTM E84).

Environmental Benefits

Polyisocyanurate insulation is a great choice for “going green”. It reduces the amount of fossil fuels required to keep the tank at a specific temperature. This will reduce the company’s air pollution by cutting down on the greenhouse gases emitted from their tank equipment. The use of recycled materials in the insulation is another great environmental benefit. In some cases, the facers are made from 100% recycled materials. This insulation is also CFC- and HCFC-free, plus it is manufactured without using any blowing agents that deplete the ozone layer.