Project Overview

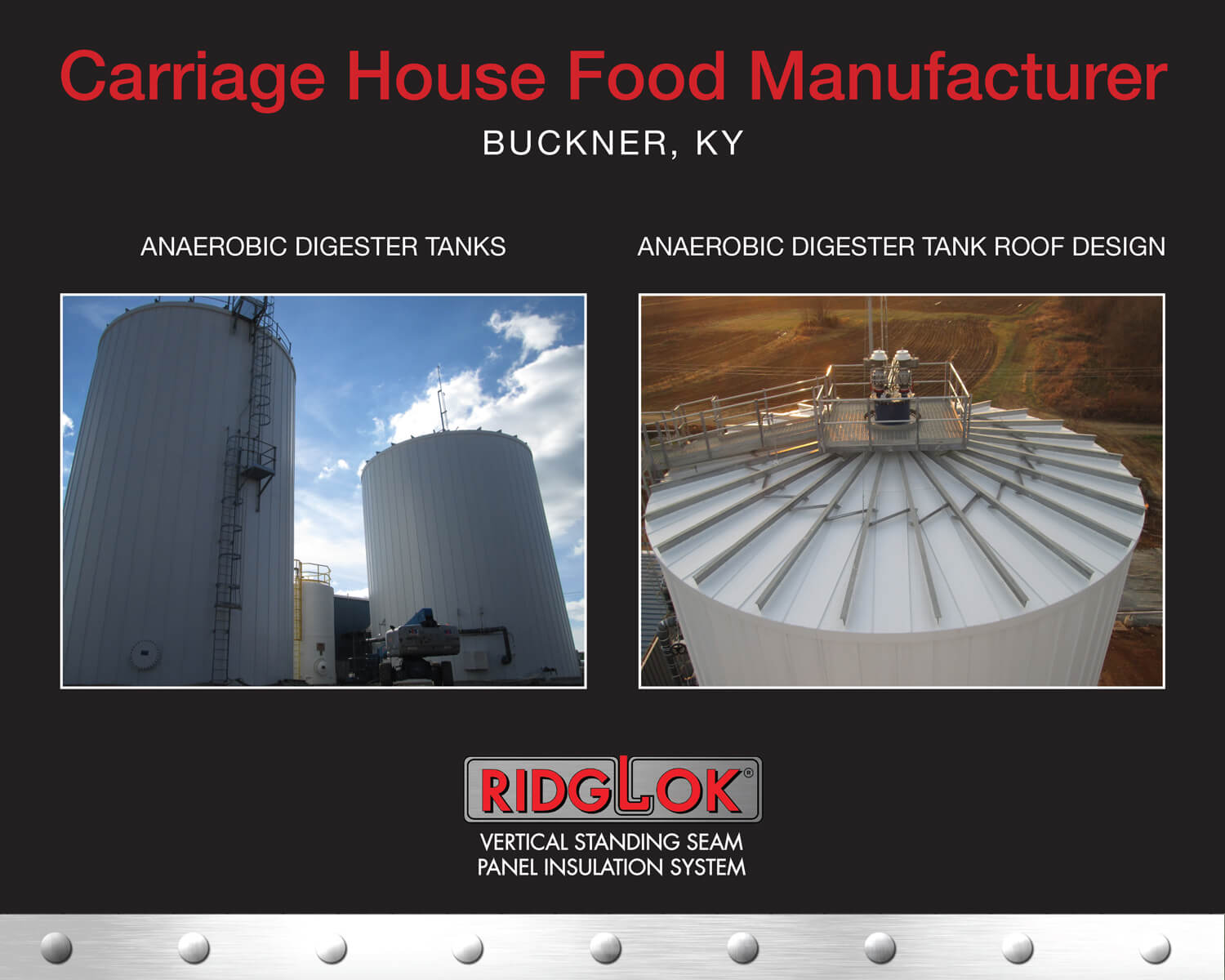

MC&I designed, manufactured, and installed the RIDGLOK® Vertical Standing Seam Panel Insulation System on two anaerobic digester tanks, located in Buckner, KY.

The tanks are utilized to hold organic waste for Carriage House Companies Inc. To read more details about the project, click here.

Anaerobic Digester Tanks

Anaerobic digesters are specially designed and insulated tanks that are used to facilitate the anaerobic digestion process under a controlled atmosphere. The anaerobic digestion process is to achieve maximum biogas production in a short period.

Organic waste is collected and stored in an airtight heated digester tank. Bacteria begins the decomposition process to turn waste into biogas, which is combusted to generate electricity, heat, renewable natural gas, or transportation fuels. RIDGLOK® Thermal Insulation is necessary to maintain the operating temperature for the anaerobic digestion process to occur.

Tank Specifications

The first tank was a 30′ in diameter x 48′ in height, EQ Tank. The second tank was a 40′ in diameter x 48′ in height, Reactor Tank.

The RIDGLOK® Insulated Panel System consisted of 0.024 stucco-embossed aluminum metal jacketing, in white, laminated to 2.0” thickness of polyisocyanurate insulation board. R-value of 13, using an external rafter roof system.

The project was completed on 12/05/2013.

Close up of external rafter design on anaerobic digester tank

Anaerobic digester tank at Carriage House Companies Inc. in Buckner, KY