RIDGLOK® Vertical Standing Seam Panel Insulation System is manufactured by MC&I Inc in Reed Kentucky and engineered to be energy efficient, durable, and cost effective. RIDGLOK® Vertical Standing Seam Panel Insulation System can be used for both heated and cold storage applications without the need for taking tank out of service. This tank insulation system can be applied to all types of tanks, including flat bolted, chimed bolted, glass lined, fiberglass, welded, stainless steel, and concrete.

RIDGLOK® belongs in your Manufacturer’s Database and in your Design Specifications.

CONTACT US to request Drawings and Specs for your projects.

INDUSTRIES:

RIDGLOK® meets and exceeds the specific requirements of multiple industries, including tank manufacturing, fire protection, wastewater treatment, petrochemical, biodiesel/ethanol plants, butane/propane, asphalt plants, chemical plants, bio-pharmaceuticals, Thermal Energy Storage (TES), power plants, food & beverage, agricultural, municipalities and many others.

CUSTOM CHOICES:

RIDGLOK® Standing Seam Panel Insulation System is built to fit the specific dimensions of your individual above ground storage tanks. The RIDGLOK® Standing Seam Panel Insulation System can be applied to vertical ground storage tanks in addition to horizontal tanks. Our tank insulation systems are manufactured with various insulation materials to meet client specifications, such as polyisocyanurate (PIR), mineral wool, fiberglass, foam glass, pyrogel and more. Metal choices include 0.024 – 0.040 stucco-embossed aluminum (SEA), 29 gauge painted steel, stainless steel, and galvalume. Tank insulation material is laminated to choice of sheathing metals, to create a customized vertical standing seam panel insulation system.

INSULATION OPTIONS INCLUDE:

-

- Polyisocyanurate Insulation Board (Non-wicking -40° F to 250° F) – Polyisocyanurate insulation board is an energy-efficient rigid insulation board composed of a closed-cell polyisocyanurate foam core bonded to reinforced aluminum foil facers on each side. The foam utilizes a CFC-, HDFC-, and HFC-free blowing agent that has zero Ozone Depletion Potential (ODP) and negligible Global Warming Potential (GWP).Polyiso insulation is an ideal choice for green energy designs because it offers reduced fossil fuel consumption. Well-insulated tanks reduce the need for energy, thereby reducing air pollution and greenhouse gas (GHG) emissions. Polyiso is the most thermally efficient rigid insulation available in the marketplace; it has the highest R-value per inch of thickness. Because of its superior R-value, tanks with RIDGLOK® Vertical Standing Seam Panel Insulation System have significantly lower heating and cooling costs than tanks insulated with other materials of the same thickness.

- Mineral wool Insulation (Sub-ambient to 1200° F) – Mineral wool provides excellent thermal insulation performance. Good thermal conductivity values help maximize control of heat loss, contributing to reduced operating costs and greater energy savings. Mineral wool can be used for service temperatures of up to 1200 degrees F (649 degrees Celsius). If mineral wool or fiberglass is chosen as the insulating material, foam glass can be applied to the bottom 18” of the exterior sidewall to prevent wicking issues.

-

- Fiberglass Insulation (0°F to 450°F) – Fiberglass insulation is lightweight and resilient. It lowers operating costs by reducing heat transfer. It is made of inorganic glass fibers with a thermosetting resin binder and formed into flexible, semi-rigid boards with factory facings. Fiberglass can be used with operating temperatures from 0 degrees F to 450 degrees F.

-

- Foamglass Insulation (-450° F to 900° F)

-

- Calcium Silicate (450° F to 1200° F)

-

- Expanded Perlite (Ambient to 1200 ° F)

-

- Pyrogel® XT-E and XT-F Insulation (-40°F to 1200°F)

- Cryogel® Z Insulation (-460°F to 257°F)

Current metal choices include 5 standard colors in 0.024 stucco embossed aluminum: White, Fawn, Grey, Black and Mil Finish. The aluminum can also be custom color matched to the surrounding structures. The 29 gauge painted steel is available in 22 colors with a flat smooth surface.

EXPERIENCED:

RIDGLOK® Standing Seam Panel Insulation System installation crews are cross-trained to identify and repair necessary items that may need attention before the RIDGLOK® Standing Seam Panel Insulation System is installed on the storage tank.

ADVANTAGES:

The RIDGLOK® Standing Seam Panel Insulation System is a smart and efficient thermal barrier, helping save money on utility costs of heating the tank. The weatherproof, double-rolled seam provides a watertight seal to protect above ground storage tanks against the elements. RIDGLOK® provides freeze protection and is little to no maintenance. Any protrusions on the tank, such as ladders, manway doors and nozzles are tightly fitted and then sealed off. The RIDGLOK® Standing Seam Panel Insulation System can be applied to both the vertical sidewall and the roof of the storage tank as well as any horizontal storage tank.

Why choose RIDGLOK® VERTICAL STANDING SEAM PANEL INSULATION SYSTEM for your tank?

-

- IMPROVES Process Control and Efficiency

-

- PROVIDES Freeze Protection

-

- PREVENTS Energy Waste – LOWERS FUEL COSTS

-

- REDUCES Heat Loss for Process Control

-

- REDUCES Energy Consumption and Emissions

-

- REDUCES Routine Maintenance Compared to Conventional Insulation

-

- REDUCES BTU Consumption

- REDUCES Carbon Footprint Contributing to a Cleaner Environment

VERSATILITY:

RIDGLOK® Panel Insulation Systems can be installed WHILE TANK REMAINS IN SERVICE to all types of tanks, including Welded Tanks (carbon, stainless steel, & aluminum), Bolted Tanks (flat bolted and chimed), Concrete Tanks, and Fiberglass – Polypropylene Tanks. RIDGLOK® attachment connections are internal of the insulation system providing protection from the weather elements to ensure longevity, making the RIDGLOK® Panel Insulation System far superior to conventional systems. All team members are OSHA & MSHA Certified with extensive aerial lift and safety training.

SAFETY:

All team members are OSHA & MSHA Certified with extensive aerial lift and safety training.

RIDGLOK® Panel Insulation WILL REDUCE tank external temperatures for “safe-touch” personnel safety.

INSTALLATION: VERTICAL SIDEWALL AND ROOF

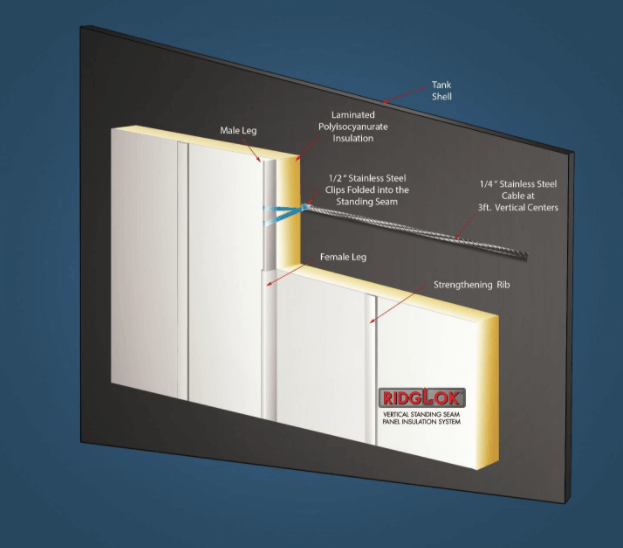

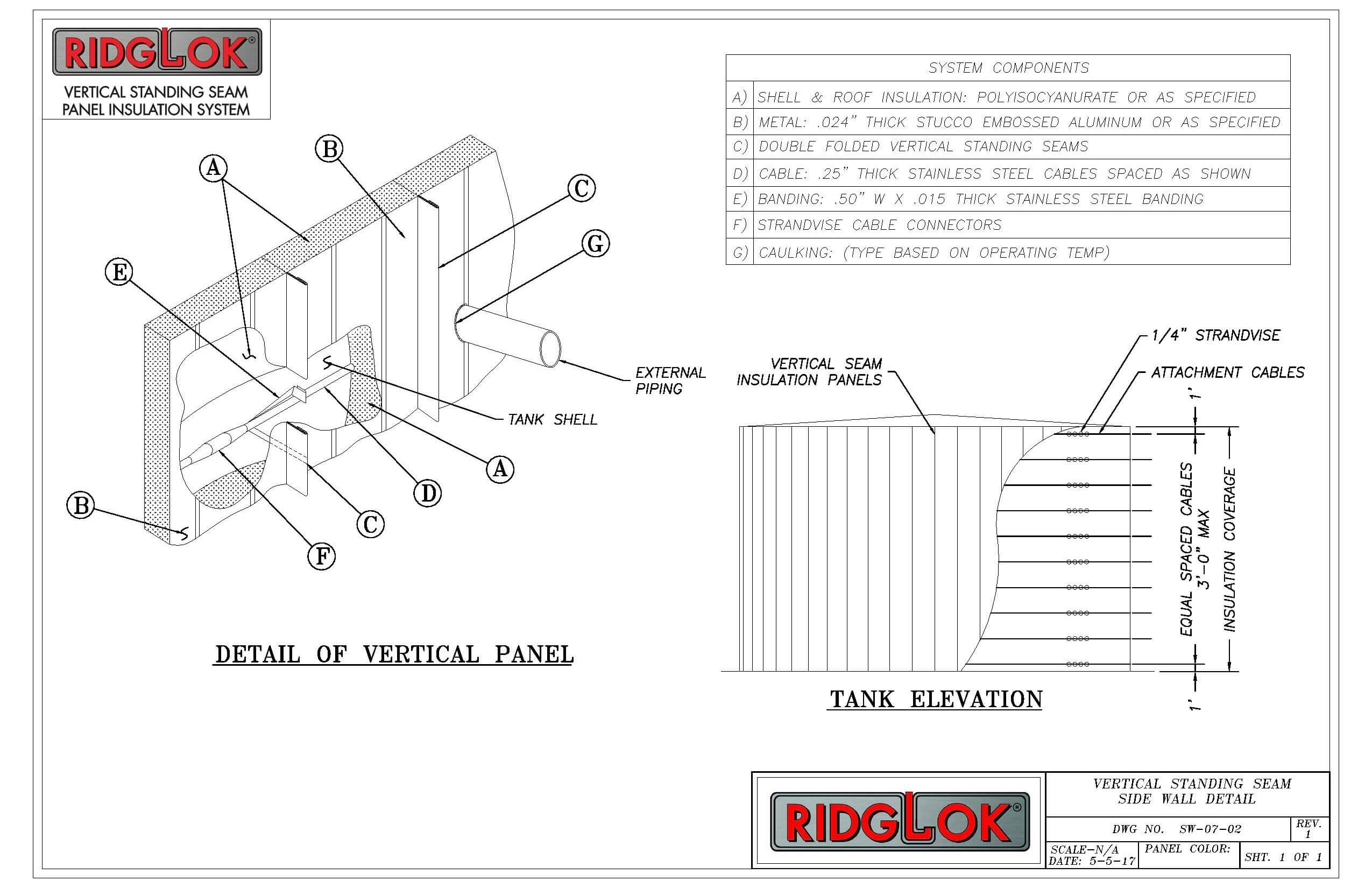

Standard RIDGLOK® Vertical Standing Seam Panel Insulation System: The outer layer is a prefabricated, roll formed 24” wide vertical panel consisting of polyisocyanurate foam insulation laminated to 0.024 stucco embossed aluminum (4 in stock factory applied colors).

For a chimed bolted tank, an inner layer of polyisocyanurate foam insulation is installed between the horizontal tank staves.

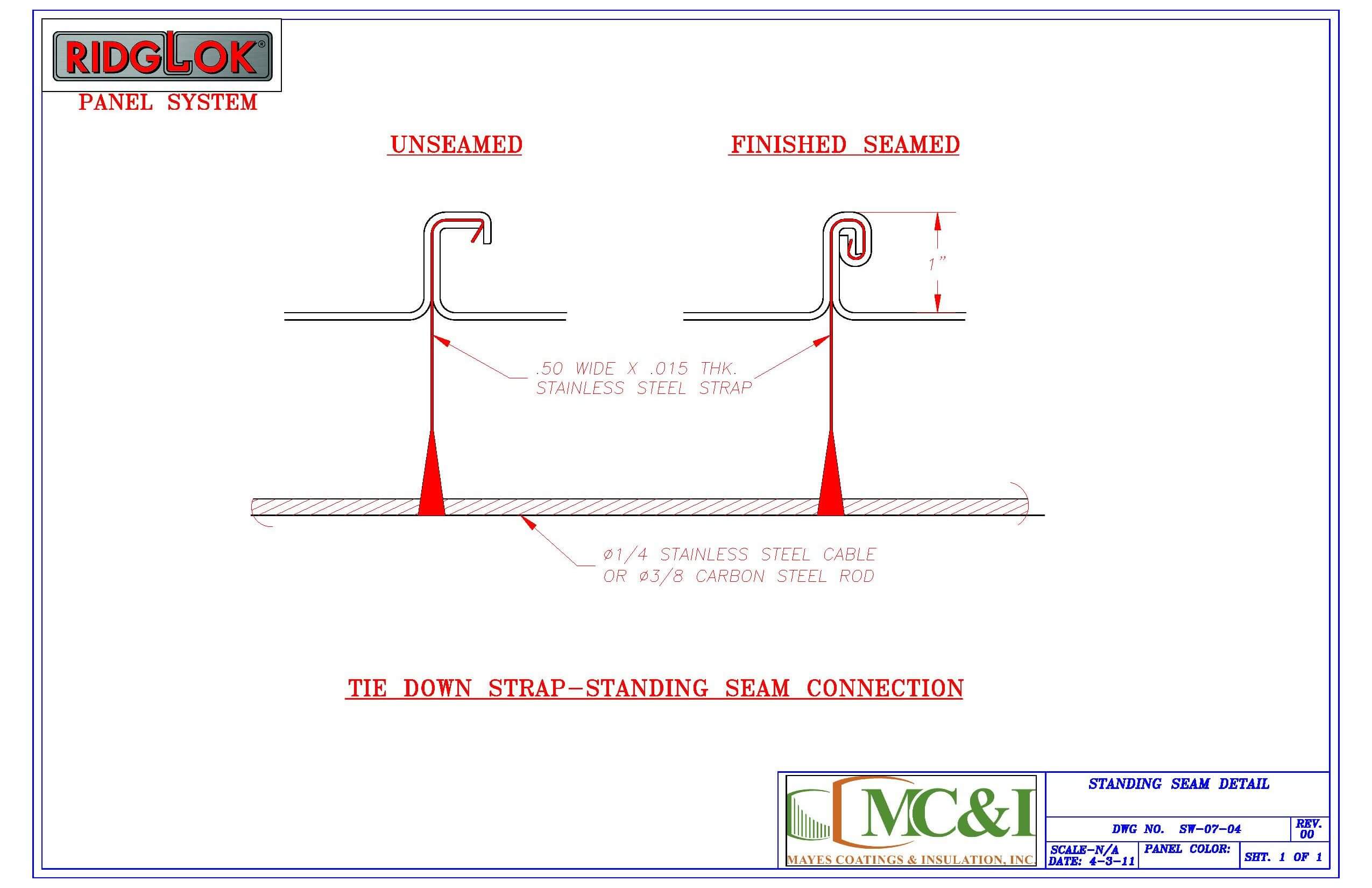

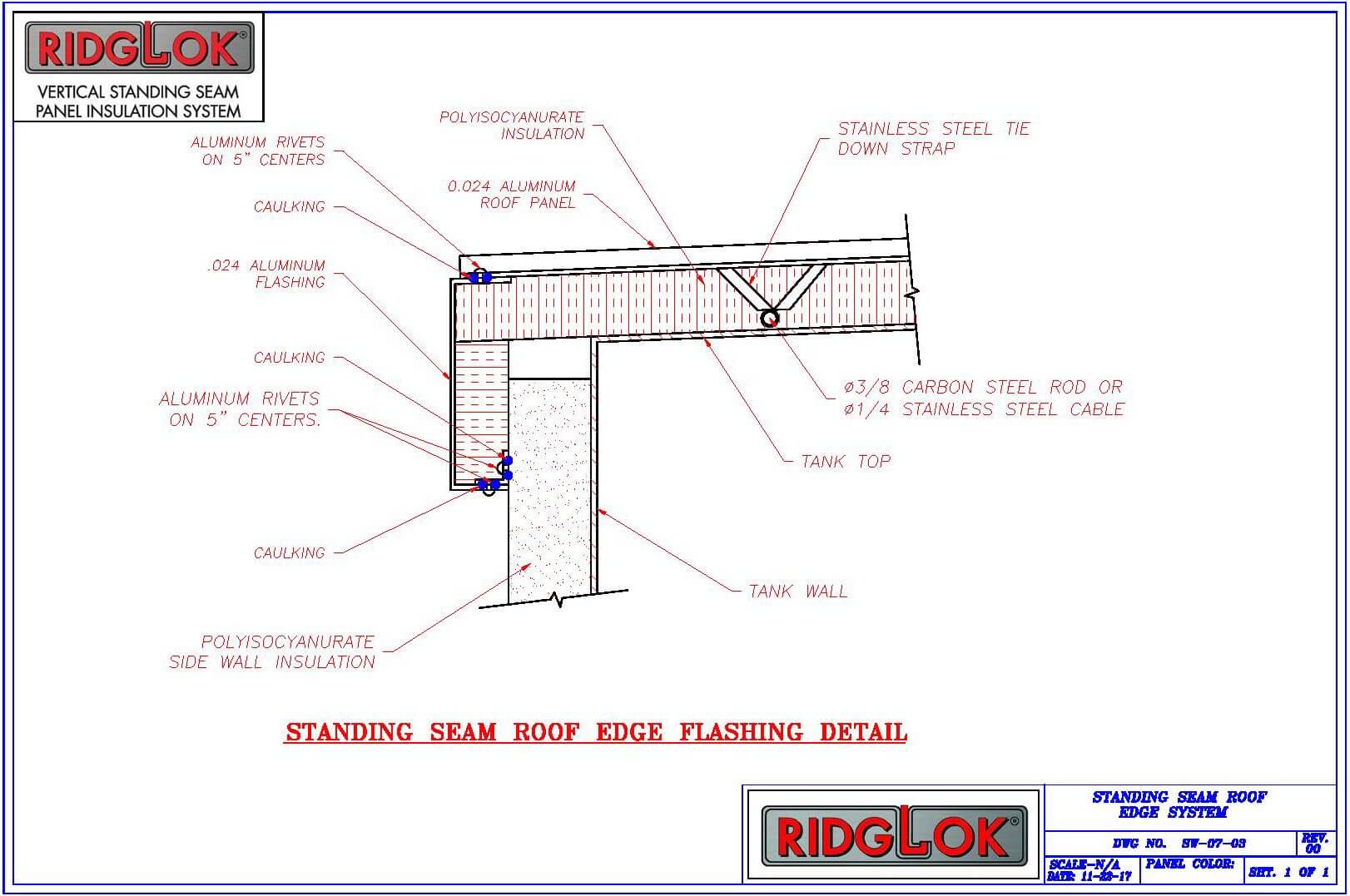

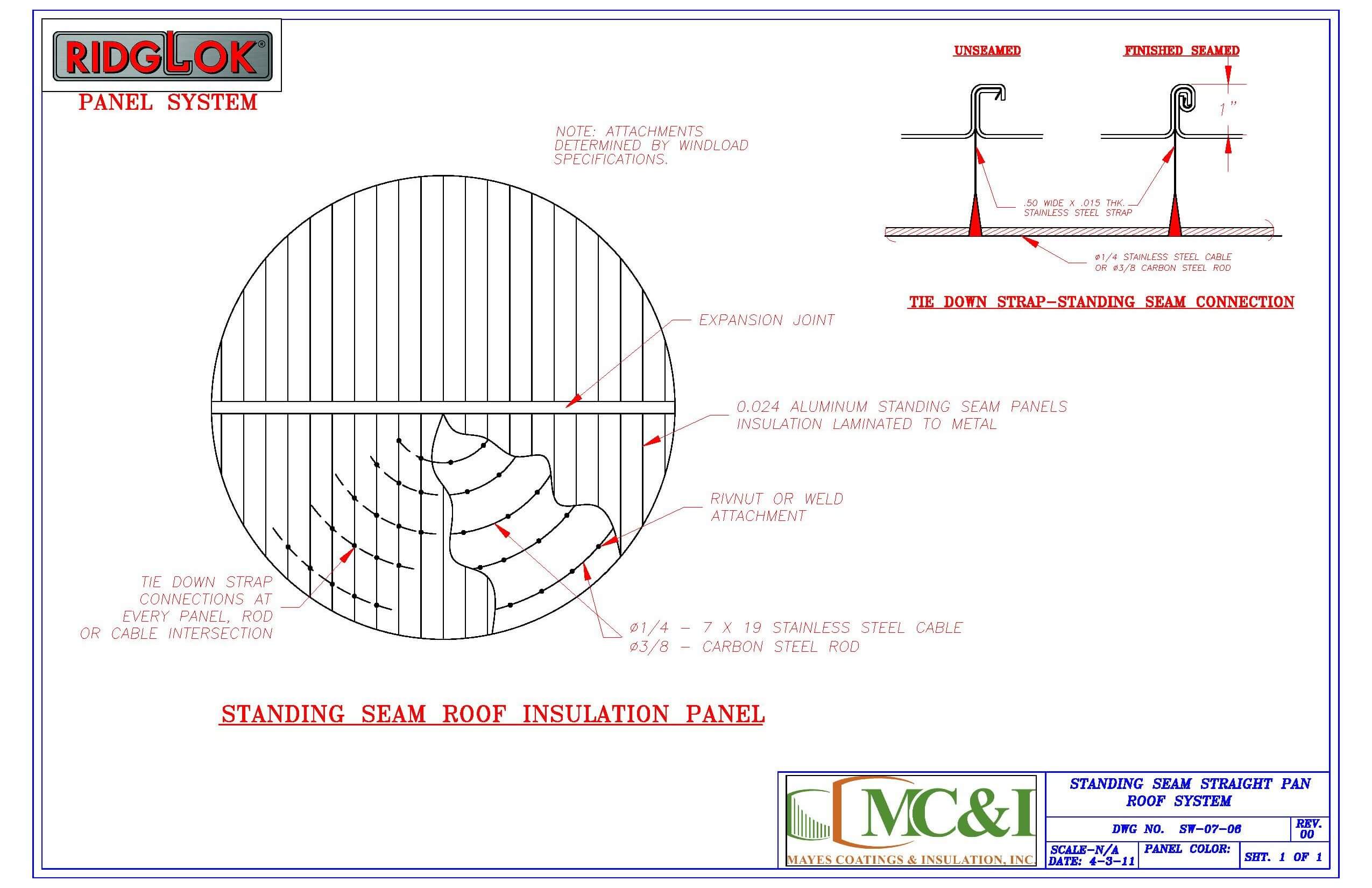

The panels are secured to a series of ¼” stainless steel cables, placed every 3 feet apart around the circumference of the tank, using .50 x .015 stainless steel strapping, which hook on to the preformed standing seam. The panels are interlocked and seamed together continuously with a double rolled seam from bottom to top.

No external banding is required with the RIDGLOK® Vertical Standing Seam Panel Insulation System. The “R” value range for the polyisocyanurate insulation is from R 6.0-27.4.

ROOF DESIGNS:

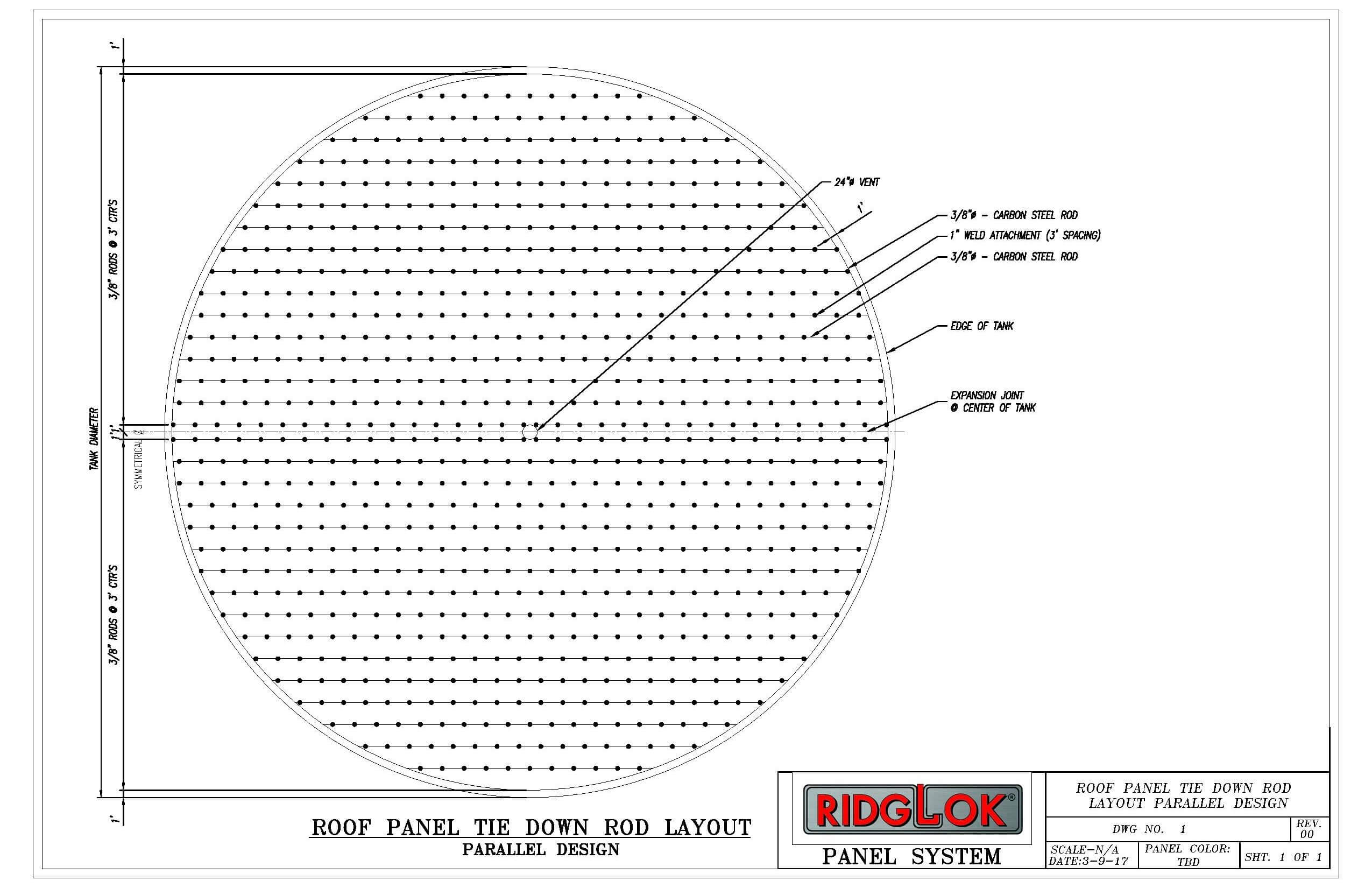

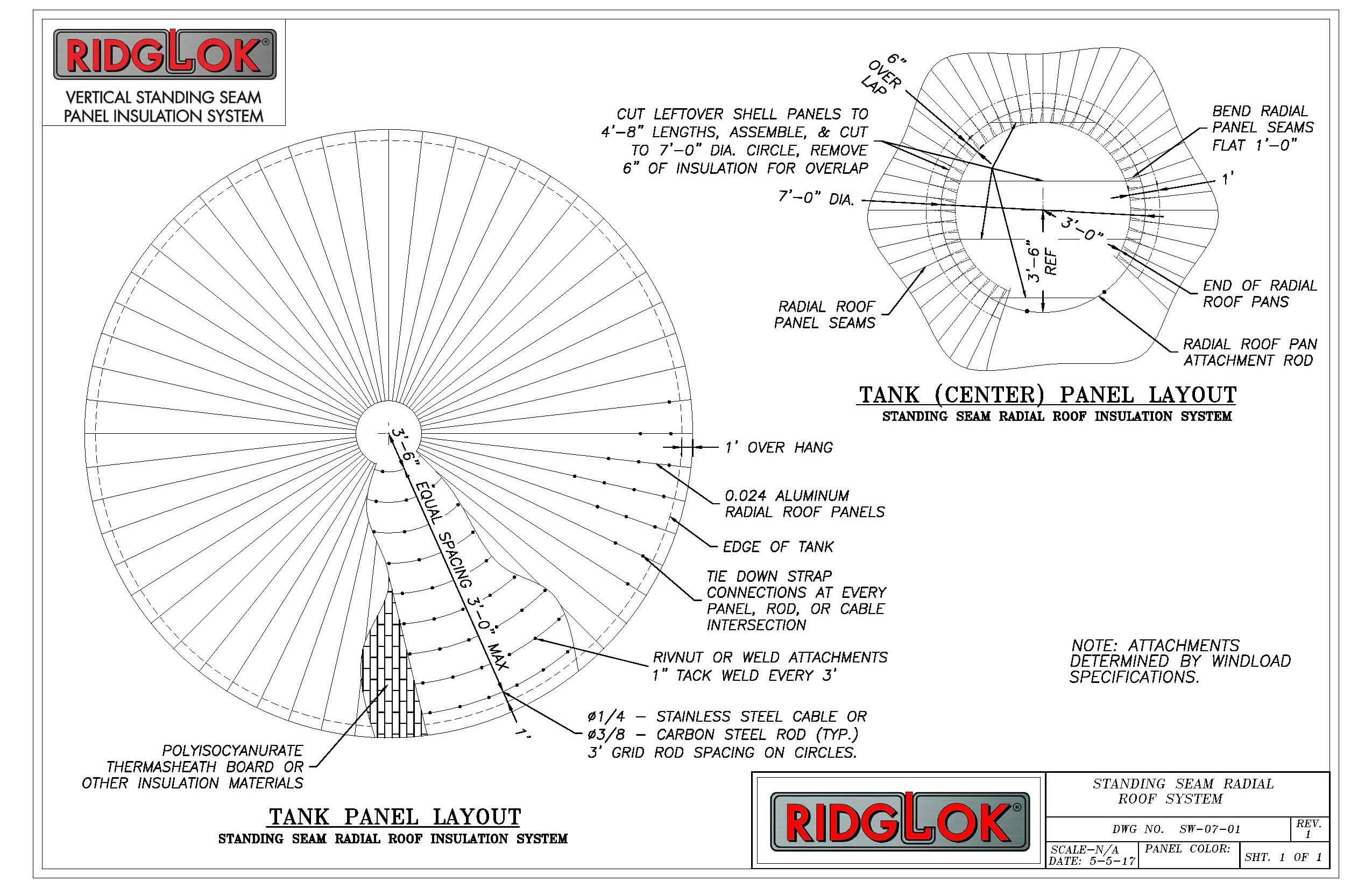

RIDGLOK® Vertical Standing Seam Panel Insulation Systems can be used to insulate various styles of tank roofs. The system can be applied in several engineered designs depending on the style of roof, such as straight panel, radial, X-design, gore, and chevron panels. The system can accommodate cone, dome and external rafter-style roofs.

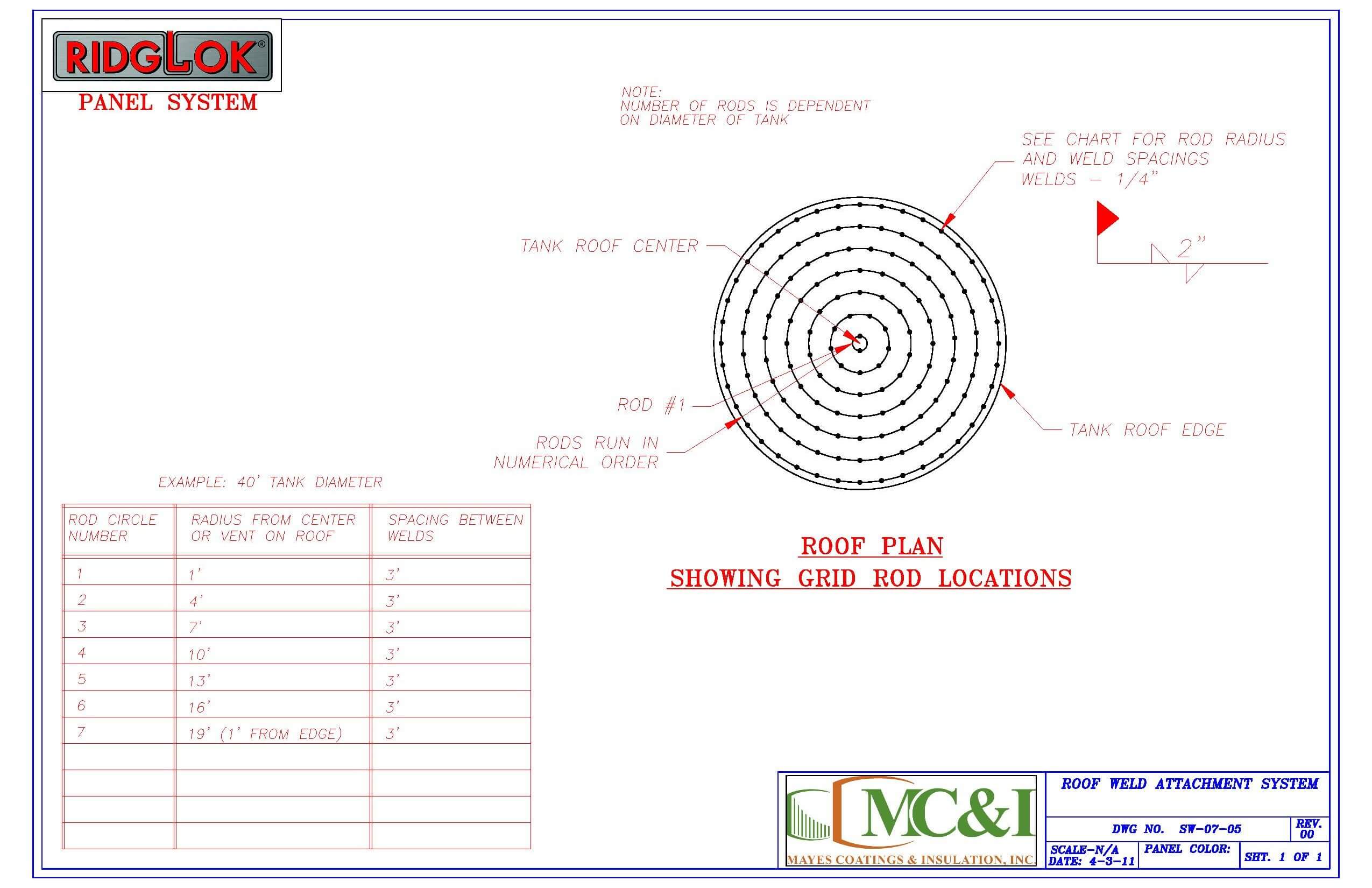

For bolted tanks, the roof panels are secured to ¼” stainless steel cables that are arrayed in concentric circles and attached to the bolts holding down the tank roof plates. For welded tanks, the roofs panels are secured to 3/8” round bar that are arranged in concentric circles 3 feet apart and tack-welded to the tank roof every 4 feet.

The storage tank roof panels will be a single thickness of polyisocyanurate foam insulation laminated to 0.024 stucco embossed aluminum. The layout design of the roof system is dependent on the style of roof on the tank.

Cost Effective – Low Maintenance

Attachment system that protects structural components from weather: